Interaction effect of elevated CO2 [ECO2], high temperature and water deficit on growth and physiology of coconut

- Increasing CO2 concentration in coconut increased photosynthesis (Pn) by 45% which, resulted in high biomass accumulation, thus improved the whole plant water use efficiency (WUE). The impact of high temperature (Tmax) around 39oC against 36oC in control was quite severe on Pn, leaf Ψ and biomass accumulation. Similarly, water deficit at 50% FC resulted in significant decline of Pn, leaf area and biomass and the effect was high in interaction with high temperature. [ECO2] could ameliorate the negative effect of high temperature and water deficit stress to certain extent.

|

Control

Control 550 ppm CO2

550 ppm CO2 700 ppm CO2

700 ppm CO2

Effect of elevated CO2 [ECO2] 550 and 700 ppm CO2 on MYD coconut seedlings |

Control

Control Elevated temperature (ET)

Elevated temperature (ET)  ET+ [ECO2] 550 ppm

ET+ [ECO2] 550 ppm

Effect of elevated temperature (ET) and ET+ [ECO2] 550 ppm on MYD coconut seedlings |

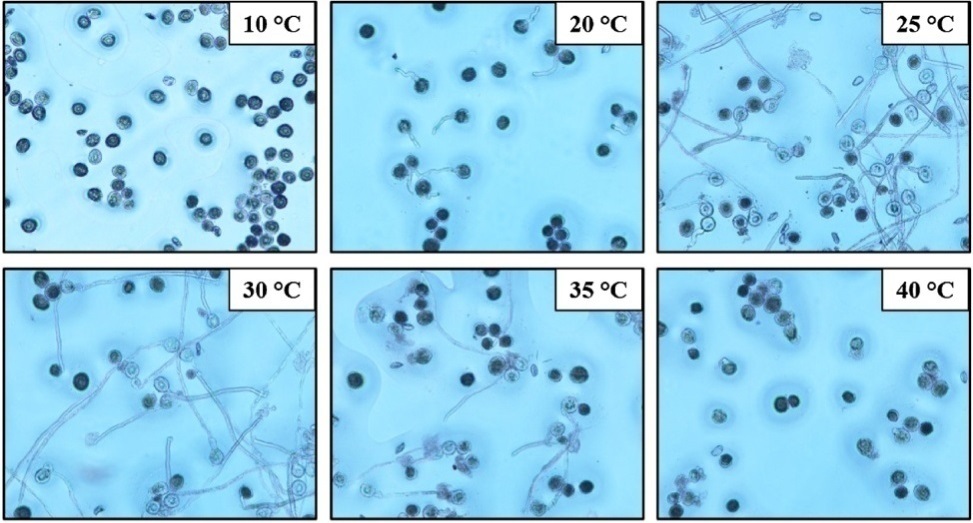

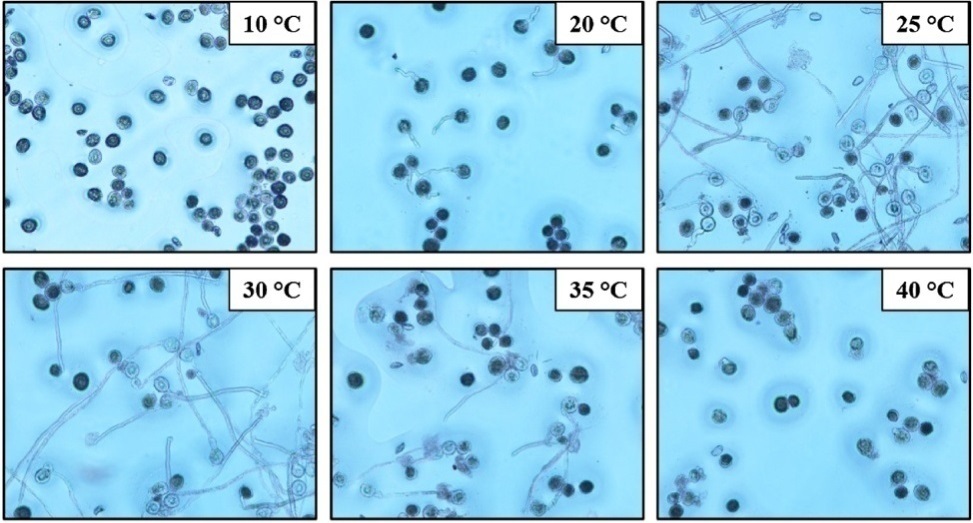

In-vitro pollen germination to screen coconut cultivars for high temperature

- An in vitro pollen germination technique was used to screen coconut genotypes tolerant to high temperature. In general, tall cultivars FMST, WCT, LCT, dwarf cultivar COD and hybrids showed better adaptability to high temperature while dwarf cultivar MYD was the least adaptable. The genotypes with higher Tmax for pollen germination and tube growth might be more tolerant to high temperature stress during flowering.

|

In-vitro pollen germination of coconut cultivars subjected to high temperature

In-vitro pollen germination of coconut cultivars subjected to high temperature

|

Level of tolerance of coconut to sea water substitution

- Growth and most of the physiological and biochemical parameters were almost on par up to 10% substation of sea water from control. At 25% and beyond the above parameters were significantly reduced thus suggesting that dwarf variety like MGD could tolerate up to 10% substitution of sea water.

|

Response of hydroponically grown coconut seedlings to different levels of sea water substitution (control through 75% substitution of nutrient solution)

Response of hydroponically grown coconut seedlings to different levels of sea water substitution (control through 75% substitution of nutrient solution)

|

Nutraceutical properties of coconut products

Anthocyanins in coconut testa

- From coconut testa, a by-product of coconut processing industries, a total of 26 anthocyanin compounds were identified (comprising 9 cyanidin derivatives; 2 peonidin derivatives, 3 delphinidin derivatives, 3 petunidin derivatives, 3 malvidin derivatives and 6 pelargonidin derivatives) using UPLC-MS/MS. Most of these anthocyanins identified are reported to possess anti-inflammatory, anti-obese, anti-diabetic, anti-oxidant and radiation -protection properties.

|

Nutritional profile of coconut haustorium

- Nutritional composition of coconut haustorium revealed that it is composed of 66% carbohydrates, with approximately 64% is soluble sugars and a considerable amount of dietary fibre and mineral nutrients. It is rich source of phenolics and has high antioxidant capacity. It can be used in baby food formulations for those who affected by lactose intolerance.

|

A technique to collect hygienic and unfermented coconut phloem sap

- To collect hygienic and unfermented sap a ‘coconut sap chiller’ was developed and the subsequent cold chain system developed enabled its storing, transport and marketing. Adoption of scientific way of tapping palm trees, processing and its organised marketing found to enhance the income of the farmers from six to eight fold as compared to the traditional way of using palm trees.

|

Mechanization of farm operations, post harvest processing for value addition and product diversification  |

Spray dried kalparasa powder was developed for the preservation of kalparasa.  |

A technology for the preservation by pasteurization and bottling of kalparasa was developed.  |

Methodology for the preparation of fresh coconut inflorescence sap (Kalparasa) based milk sweets (Kalparsa-Kalakand, Kalparasa-peda, Kalparasa-Sandesh, Kalparasa-Kachagolla) has been standardised.  |

A coconut sugar based chocolate (Kalpa Choco/Kalpa Bar Dark Chocolate and Kalpa Drinking Chocolate), purely with plant based ingredients (cocoa powder, coconut sugar, natural vanilla extract and sunflower lecithin), has been developed.  |

| Process parameters i.e. soaking time, drying time and drying temperature) were optimized for the production of refined white sugar and kalparasa sugar based coconut chips. |

A delicacy called tender nut water jelly has been prepared from tender coconut water with the addition of a gelling agent.

|

- An ideal combination of coconut sugar, cocoa powder and cocoa butter was standardized for preparation of homemade chocolate devoid of dairy products.

- A complete processing protocol (consisting of fermentation, drying, roasting and winnowing of cocoa beans, refining of nibs with coconut sugar and cocoa butter, tempering, moulding, refrigeration, demoulding, packaging and storage) for the preparation of bean to bar chocolate using coconut sugar was standardized.

|

- Protocol for coconut milk-based paneer was standardized using second and third extractions of coconut milk followed by blending with different protein sources such as soy milk, dairy milk, egg albumin and skim milk powder in optimized concentration.

|

- Coconut shell removing machine (150 nuts/h capacity) was designed, fabricated, evaluated, commercialized and transferred to stakeholders.

|

- Self loading arecanut dehusker with dust control system (50 kg/h capacity) and grading unit was designed, fabricated, evaluated at different farmers’ field and adopted by different stakeholders

|

| A pilot level (5-15 kg/h) process and technology for the production of extrudate from coconut milk residue and virgin coconut oil cake have been evaluated at CIFT, Kochi and CIPHET, Ludhiana. |

Virgin coconut oil cake based muffins were developed.

|

| Coconut milk residue based pasta, fried snacks, biscuits and rusk were developed.

|

Coconut milk powder using 4% sodium caseinate and 17.5% maltodextrin has been standardized with at least three months shelf life under ambient condition.

|

- Ready to cook kheer mix was formulated using coconut milk powder, coconut sugar and vermicelli with two months shelf life under ambient condition.

- A prototype for trimming machine for tender coconut has been developed, demonstrated and transferred to one Coimbatore based machine fabricator.

- Complete preservation protocol for trimmed tender coconut has been successfully developed, demonstrated and transferred to two entrepreneurs.

- Pilot plant (5-15 kg/h batch) for the production of coconut milk residue and virgin coconut oil cake based extrudates has been installed and commissioned.

|

A complete package of technology for the production of extrudates from the different combinations of coconut milk residue, virgin coconut oil cake, coconut haustorium, maize, broken rice and millets has been developed, demonstrated, commercially launched in the name of ‘Kalpa Krunch’ and successfully transferred to two entrepreneurs.

|

| A complete package of technology for the production of coconut milk, coconut sugar, tender coconut water and tender coconut pulp based frozen delicacy (ice cream) has been developed, demonstrated and successfully transferred to three entrepreneurs. |

|

|

- ICAR-CPCRI in collaboration with ASPEE Mumbai has developed a tractor mounted air blast sprayer prototype, which delivers the fungicide solution to a height of 30 m which is effective in well laid out gardens under arecanut monocropping system.

- A prototype of the air blast sprayer mounted on a mini tractor, operated by the power taken from its PTO, has been developed.

- Spraying of plant protection chemicals could be done form the ground and the spray could reach a height of 30m.

|

Soil & water conservation and water harvesting structures.

- Loose Boulder Check Dam (LBCD) constructed using boulders from the near vicinity of the checkdam and Dry Rubble Check Dam (DRCD) constructed using blasted granite stones bought from nearby granite quarries were studied.

- Stability of LBCD (only 19% was intact) was much inferior to that of DRCD (43% was intact). Among the different methods of construction, the cement concreting provided at the top of the checkdam improved its strength

- The study revealed that the irrigation water potential and the local groundwater potential increased due to the construction of check dams.

|

Patents filed

- Ghosh DK, Apurba B, Dey, B., Ghosh K, Hebbar KB and Chowdappa P. Method of the Preparation of fresh coconut inflorescence sap (Kalparasa) based sweets. Patent Filed No: E-12/50/2016-KOL; Commercialized to sweet maker Pilu Modak in West Bengal.

- K.B. Hebbar & P. Chowdappa: Method for aseptic extraction of tender nut water as frozen ball and soft endosperm (kernel) from trimmed young coconut. E-12/449/2018/CHE. Not yet commercialized.

|